Printing

Printing

We have several printing techniques: digital printing, flexo printing, pad printing and brand stamping. We can print on almost all our products. By printing a logo, a design or a text, your packaging gets an exclusive look entirely according to your wishes. We would be happy to give you non-binding advice regarding the best printing method for your product. You will also receive a sample of your design.

Digital Printing

When to choose digital printing?

Digital printing is interesting for smaller production orders, can be delivered quickly, multiple colors are possible and relatively cheap.

How does it work?

The design is sent from the computer to the printer. The wood is placed on a plate above which a print head moves that drops the ink on the wood. Because the ink falls on the wood, there is no direct contact which may lead to small texts appearing less sharp.

Flexo printing

When to choose flexo printing?

Large print order runs, razor-sharp compared to digital printing, several colors are also possible here.

How does it work?

The print that has to be printed on the wood is projected on a roll (print roll), this roll is then turned along another roll full of ink (ink roll). Another roller pushes the wood against the print roller so that the design is properly pressed onto the wood. Thanks to this technique, the wood comes into direct contact with the design, making it razor-sharp.

Pad printing

When to choose pad printing?

Pad printing is used for printing oyster knives and mussel pans as only pad printing can print on non-flat objects. This way it is possible to print logos. It is possible to print one or more colors. 1 tampon (rubber stamp) is used per color.

How does it work?

The design is photographically applied to a cliché (a metal plate). Through the tampon (rubber stamp) the design of the cliché is transferred and printed on the article.

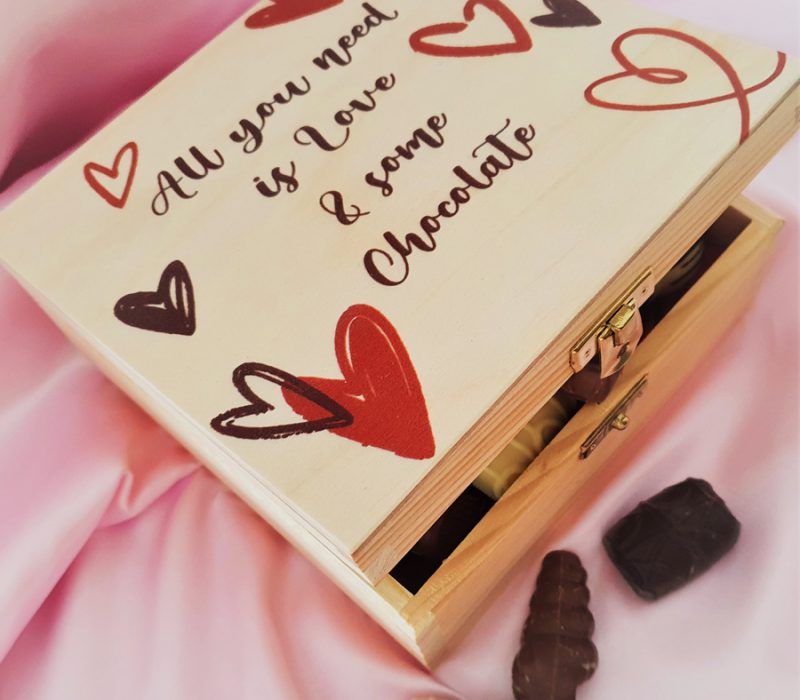

Branding stamp

When to choose a branding stamp?

Burning on wood gives a beautiful natural look. A branding stamp is ideal for frequent use / large quantities of wooden products with your logo or company data.

How does it work?

With brand stamps we leave a permanent brand mark in wood. At the bottom of the branding stamp is a metal heating element, which burns the logo in the wood.